Technology

Leveraging new potential

Genuine innovations arise when the obvious is questioned

Do batteries have to burn? Do batteries have to age? Do batteries have to harm the environment? With our proprietary HPB Technology we are redefining the limits of conventional batteries.

Safer – Longer lasting – Greener

The HPB Solid-State Battery redefines safety, reliability, and sustainability in stationary energy storage. Powered by our proprietary HPB Technology, it combines intrinsic safety, exceptional cycle life, and a significantly improved environmental balance – setting new standards for next-generation energy systems.

Unlocking new possibilities

For our license partners, this means new business potential through longer product lifecycles, reduced warranty risks, and scalable integration across applications. It enables efficient, high-performance solutions across sectors – from stationary energy storage to mobility.

The fifth generation of battery technology

A new fundamental technology – discovered by coincidence

Our company actually originated from a coincidental discovery in research. We saw this coincidence as an opportunity and developed it into a superior battery technology. As a new fundamental technology, HPB Technology can make a significant contribution to the success of the energy and mobility transition by combining a unique set of properties.

The top layer makes the difference

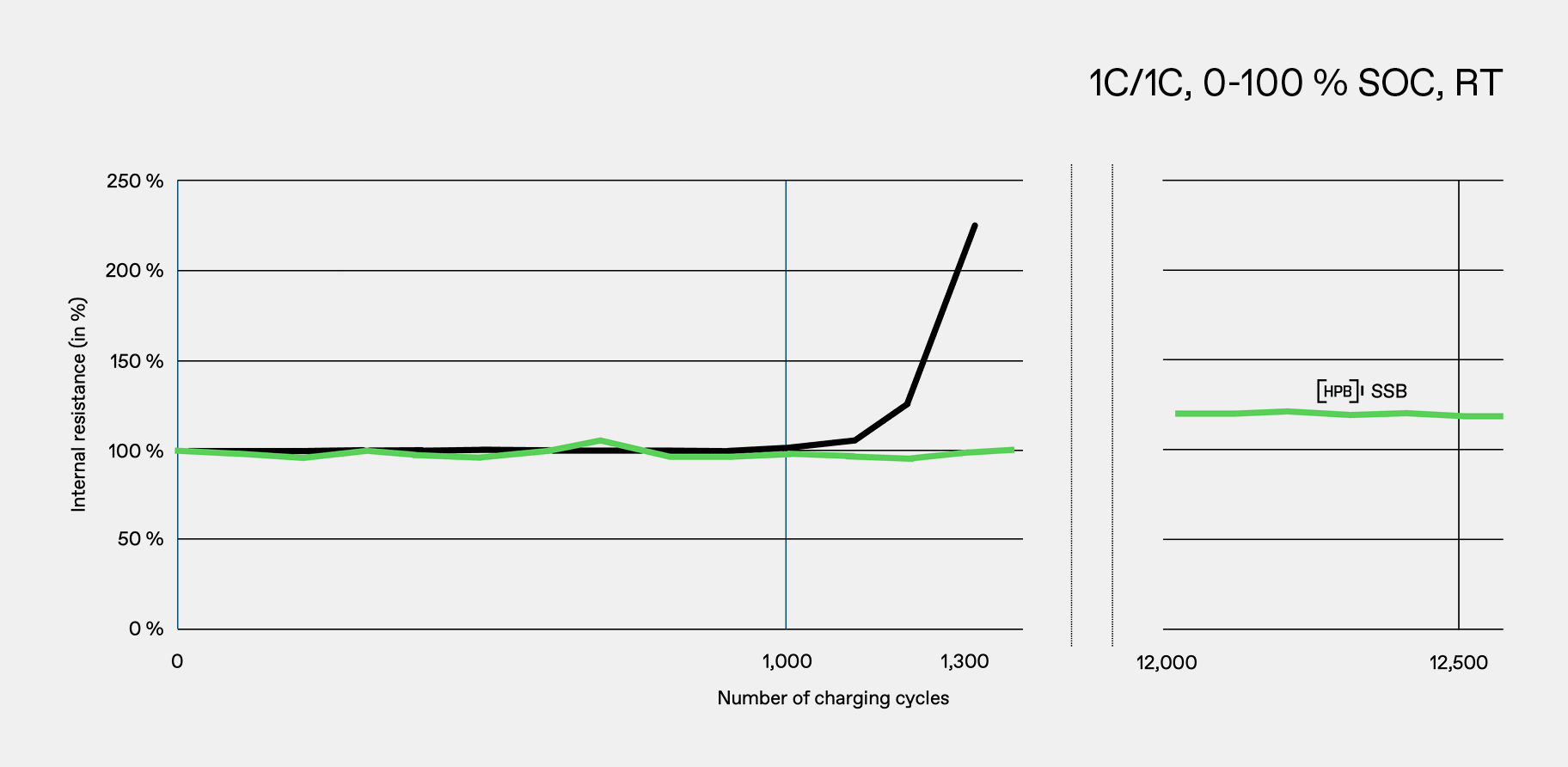

Conventional lithium-ion batteries age because a top layer forms especially on their anodes through charging and discharging. This grows over time and with each use, even faster the more intensively the battery is used. This growth of the top layer consumes capacity and increases the internal resistance, the performance of the battery decreases.

With our innovative HPB Technology, a very thin top layer forms during first charging. After that, it grows no further. Through the use of our patented HPB Solid-State Electrolyte, internal resistance remains virtually constant throughout the service life. No matter how much the battery is used.

The fifth generation of batteries:

1880 Lead-acid

1900 Nickel-cadmium

1980 Nickel-metal hydride

1990 Lithium-ion

2018 HPB Solid-State Battery

Sets new

benchmarks

12,500+ cycles and ongoing

While conventional lithium-ion batteries have to be replaced after approx. 1,250 charging cycles*, with hourly charging and discharging, the HPB Solid-State Battery currently has at least 12,500 charging cycles, with a comparable load. Since these cycle life test cells have not yet reached the end of their life, this number will continue to increase steadily.

The HPB SSE

at the core

Superior and scalable

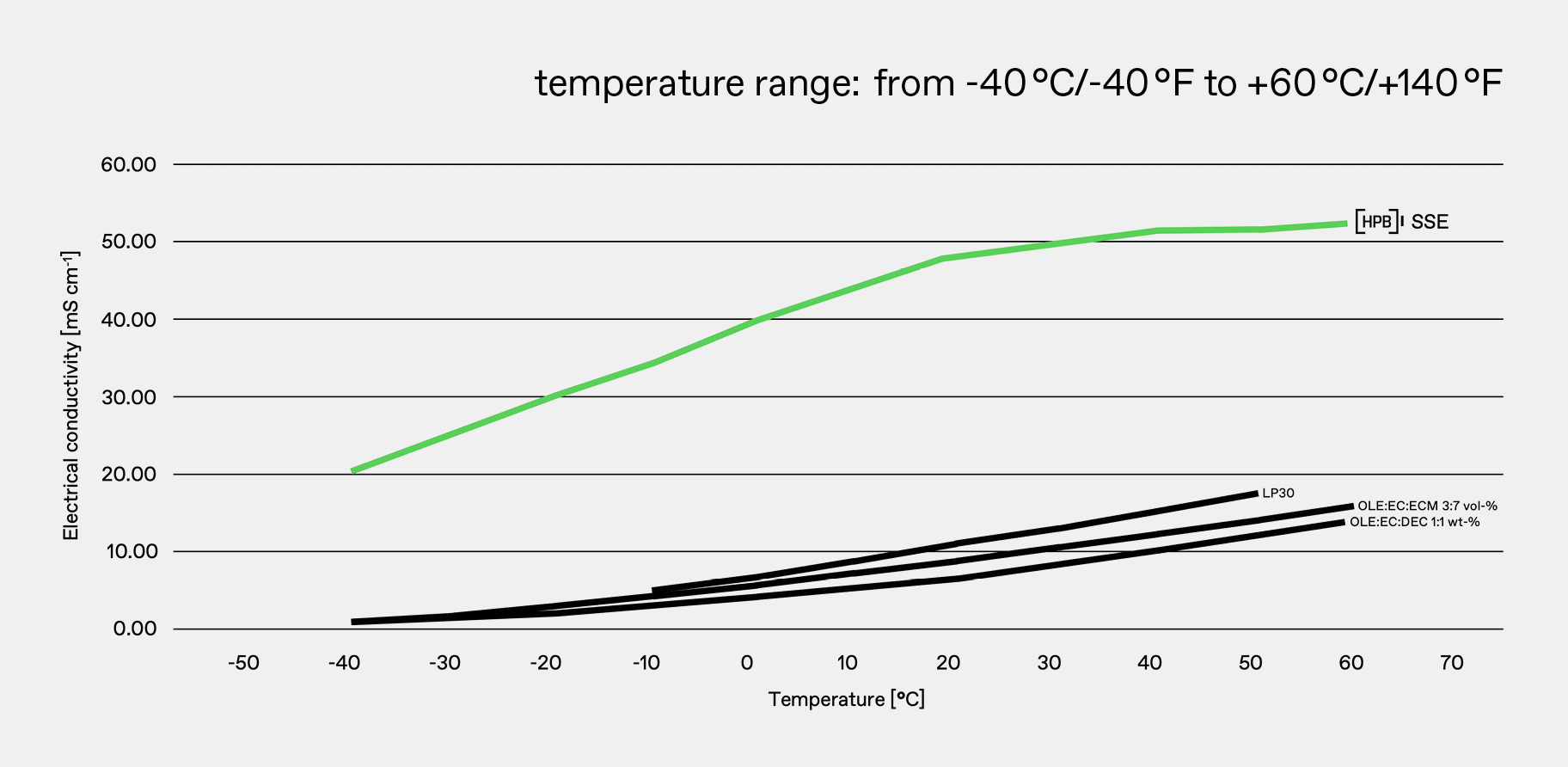

Even at minus 40 °C/-40° F, the HPB Solid-State Electrolyte (SSE) shows a siginficantly higher ionic conductivity than conventional liquid electrolytes in their optimum at plus 60 °C/140 °F.

Furthermore, the HPB Solid-State Electrolyte is easy to produce, as it can be manufactured based on known production processes from conventional lithium-ion batteries with liquid electrolytes.

Sources: [1] J. Landesfeind, H. A. Gasteiger. J. Electrochem. Soc. 2019, 166(14), A3079-A3097. URL: https://iopscience.iop.org/article/10.1149/2.0571912jes | [2] T. R. Jow, K. Xu, O. Borodin, M. Ue (Ed.), Electrolytes for Lithium and Lithium-Ion Batteries, 2014, Modern Aspects of Electrochemistry Vol. 58, Springer, New York. | [3] T. B. Reddy (Ed.), Linden's Handbook of Batteries, 2010, 4th ed., McGraw-Hill Education Ltd.

High performance

in any climate

Say goodbye to seasonal limits

Energy independence requires reliability in every climate. HPB Batteries deliver exceptional low-temperature performance, maintaining high capacity and power output even far below freezing (down to -40 °C/-40 °F).

Where conventional lithium-ion batteries struggle to operate efficiently in near-zero conditions, HPB’s solid-state chemistry ensures safe, consistent performance from Arctic to desert environments – making it ideal for grid storage, charging infrastructure, defense applications and more.

HPB (2025): low-temperature performance HPB Solid-State Battery

Link ↗

Ready to produce at scale

The Chemistry advantage: Liquid input, solid output

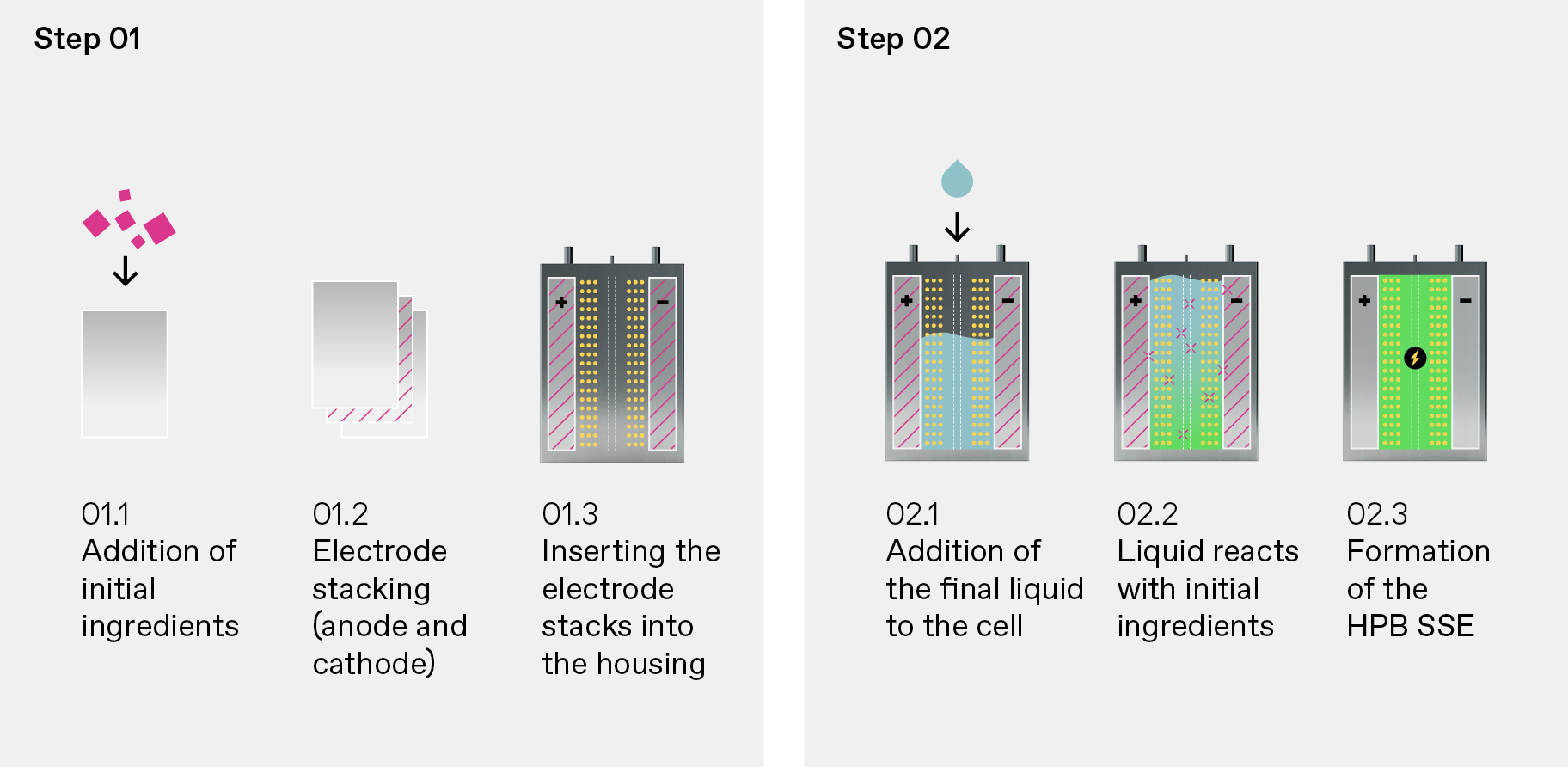

While many research groups focus on building solid-state electrolytes outside the battery cell 1 – facing significant physical limitations 2 – HPB takes a fundamentally different path.

Drop-in Process

Our HPB Solid-State Electrolyte forms directly inside the cell from initial solid and liquid ingredients. This chemical in-situ formation bypasses key production barriers of conventional all-solid-state designs and dramatically simplifies manufacturing.

The production process of the HPB Solid-State Electrolyte (SSE) inside the battery cell is comparable to that of a two-component glue: The addition of a liquid facilitates a chemical reaction with the initial solid ingredients, resulting in the formation of the HPB Solid-State Electrolyte directly within the battery cell.

Recognised scalability

The use of liquid raw materials has another decisive advantage: it makes it possible to use established production technology for battery cell production – technology that is used in the manufacturing of conventional lithium-ion batteries with liquid electrolytes. This means that the production of our HPB Solid-State Battery can be scaled up without the need to develop completely new production technologies.

Engineered for stationary applications

A clear focus

The focus of our technology development is on stationary applications ↗ (e.g. solar power storage). To this end, we are

optimizing the HPB Solid-State Battery using the patented

HPB Solid-State Electrolyte. The subject of battery

development is the interaction of the three core components

of a battery: anode, cathode and the HPB Solid-State Electrolyte as a complete battery cell. The development also includes

industrial production through to the battery module (several battery cells combined form a battery module).

Not what you were looking for?

For automotive applications, we offer licensing of our non-flammable, highly conductive, and chemically robust HPB Solid-State Electrolyte as a single-component for your own battery development.

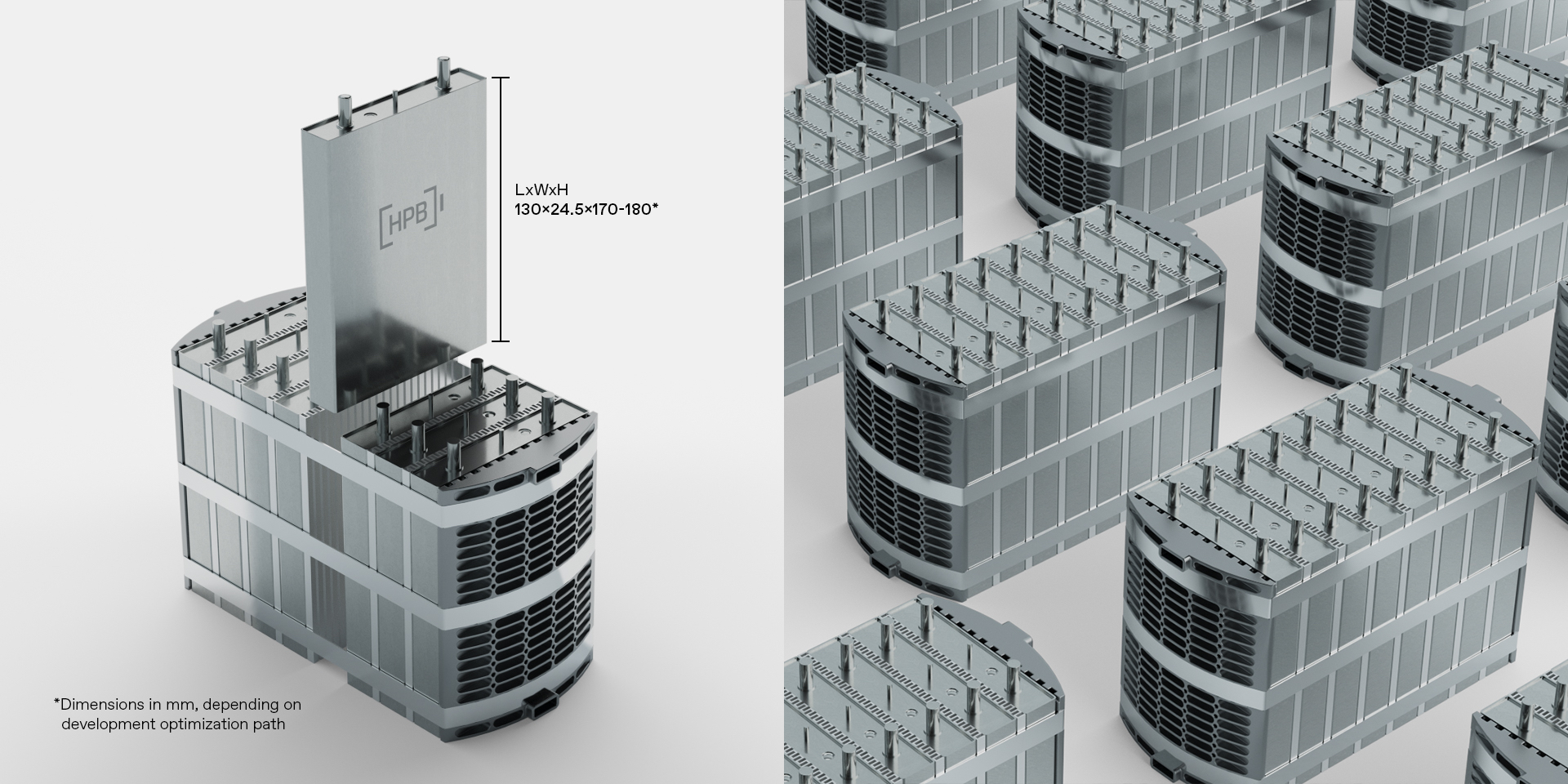

Modular design:

One size fits many

HPB modules follow a standardised, scalable architecture

Each module contains 8 cells × 50 Ah = 1.28 kWh.

Systems can be configured for diverse applications:

Home storage system ≈ 10 kWh (8 modules)

Industrial buffers ≈ 200 kWh (160 modules)

This modular concept simplifies integration, service, and scaling – from home storage to large-scale grid systems.

Technology Comparison

HPB Solid-State Battery vs. Conventional Lithium-ion batteries

Relevant features at a glance

Patent applications

Patent application 1

↗ Rechargeable electrochemical cell (in log-in language)

Patent application 2

↗ Electrolyte for rechargeable electrochemical battery cells (in log-in language)

Patent application 3

↗ Electrode-separator element with a ceramic separator layer

(in log-in language)

Patent application 4

↗ Rechargeable electrochemical cell with ceramic separator layer and indicator electrode (in log-in language)

Patent application 5

↗ Solid state electrolyte for rechargeable electrochemical battery cells (in log-in language)

FAQs

- What is special about HPB Technology?

In short: a production-ready all-solid-state battery with superior properties. Longevity, sustainability, and safety take centre stage. Based on over 30 years of fundamental research into battery ageing, we have succeeded in understanding and preventing the ageing processes in conventional lithium-ion batteries. The fact that this also works in practice has been proven by measurements on cells that have been cycled for over three years under harsh conditions (1C/1C charge/discharge at 0-100% state of charge) - with over 12,500 charging cycles to date. The basis for this is the patented HPB Solid-State Electrolyte, a new type of electrolyte that is characterised not least by its very high ionic conductivity over a wide temperature range (tested for -40 to +60°C), which is far higher than the conductivity of conventional liquid organic electrolytes.

- For which fields of application is HPB Technology suitable?

The focus in the development of the HPB Solid-State Battery is on stationary applications (home storage, industrial storage, large-scale storage for grid stabilisation, etc.). This is where the advantageous properties of our technology come into their own - not least the extremely long cycle life, which enables multiple use of storage systems and thus completely new business models. The field of stationary applications is just as important for a successful energy transition as the field of mobile applications, which has been the focus of much more debate to date, and also represents an enormously large, exponentially growing market.

- What are the performance data of the HPB Solid-State Battery?

At a nominal voltage of 3.2 V, each cell has a capacity of 50 Ah (160 Wh). This capacity can be fully utilised, i.e. from 0-100 % state of charge. The HPB Solid-State Battery is not only resistant to deep discharge, but can also be fast-charged: 2C/2C (i.e. half hourly) charging/discharging is possible as a continuous load, the minute load capacity is 6C. The energy density is up to 150 Wh/kg or 350 Wh/l. Eight cells are combined to form a module with a capacity of 1.28 kWh, and eight modules are combined to form a home storage battery with a capacity of 10.24 kWh. Based on this modular design, HPB Solid-State Batteries can be scaled as required, and the voltage and current can be adapted to the respective requirements through serial or parallel connection.

- What makes the HPB Solid-State Battery so safe to use?

Conventional lithium-ion batteries are associated with a certain risk of fire and explosion, which impairs their acceptance (e.g. in the home storage sector) and limits their application potential. In contrast to conventional liquid organic electrolytes, the HPB Solid-State Electrolyte is not flammable. Therefore, not only does the HPB Solid-State Battery not pose a fire hazard, but it is also considerably less flammable than conventional lithium-ion batteries when exposed to an externally caused fire. Safety also includes potential harm to people and the environment if battery cells are damaged in an accident, for example. Significant advantages over conventional batteries can also be expected in this area.

- Which substances are contained in the HPB Solid-State Battery?

The active materials used in the HPB Solid-State Battery are lithium iron phosphate (LFP) and graphite. In addition, there is stainless steel for the battery housing, nickel for the current collectors and the ingredients for the solid-state electrolyte. Unlike in NMC batteries, the nickel is present in pure form, which ensures good recyclability. None of the materials used have a high criticality, such as cobalt in NMC batteries.

- Why is the HPB Solid-State Battery ready for series production?

The HPB Solid-State Electrolyte forms after the addition of a liquid ingredient inside the cell. This allows two challenges faced by other solid-state battery approaches to be solved at once: A close contact is created between the HPB Solid-State Electrolyte and the electrodes, which is absolutely essential for good conductivity. What's more, established production technology for lithium-ion batteries with liquid electrolytes can be used to set up series production. We co-operate with a network of European plant manufacturers who have already gained experience with a precursor technology and are ready to set up production. The planning of production will be supported up to plant level (both for pilot production and for gigafactories).

- How far does the patent protection of HPB developments extend?

HPB Technology is protected in 96 countries worldwide and therefore in all relevant markets. The HPB Solid-State Electrolyte as the core element of our technology is protected as a substance and is therefore also "immune" to the possible development of alternative production methods. All patent specifications are freely available on our homepage at https://www.highperformancebattery.ch/en/medien-corner.php.